In the intricate world of sewing, the balance of tension is paramount, especially when it comes to the bobbin. A perfectly tuned bobbin can be the difference between a project that looks amateurish and one that appears professional. Among the diverse range of sewing machines, the Janome stands out as a favorite for many.

Thus, understanding “how to adjust bobbin tension on Janome sewing machines” becomes a vital skill for every sewing enthusiast. Whether you’re encountering irregular stitches or just looking to refine your skills, this guide will provide comprehensive insights and practical steps to ensure your Janome machine always delivers impeccable results.

Understanding Bobbin Tension: A Primer

Before delving into adjustments, it’s vital to comprehend what bobbin tension truly is. At its essence, bobbin tension dictates the resistance on the thread as it unravels from the bobbin. Paired with the top thread tension, it forms balanced, even stitches. When in sync, your stitches exhibit symmetry, appearing consistent on both fabric sides.

But if the bobbin tension deviates from the ideal, problems arise. Uneven stitches, looping, or fabric puckering can all be traced back to tension imbalances. Recognizing these signs is your first step to achieving sewing perfection.

The Basics of the Janome Sewing Machine Bobbin System

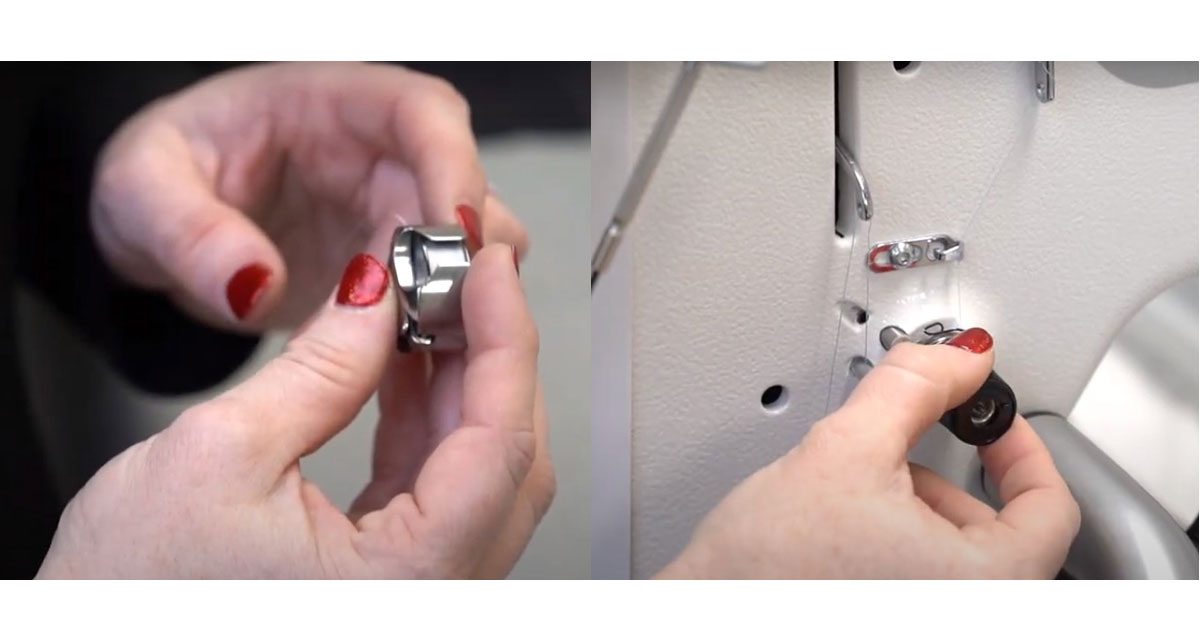

Janome, a brand synonymous with quality and precision, has a unique bobbin system. Central to this system is the bobbin case, which houses the bobbin and contains the critical tension screw.

For those unfamiliar, this screw’s minute adjustments can drastically alter the bobbin tension. Finding it is straightforward: it’s usually a small screw on the side of the bobbin case. However, before any adjustments, it’s imperative to acquaint yourself with the starting tension and understand how your specific Janome model responds.

Step-by-Step Guide: Adjusting Bobbin Tension on Janome Sewing Machine

1. Prepare the Machine:

Why It’s Important: Keeping your machine pristine is the foundation of any sewing task. Any debris, lint, or stray threads can interfere with the bobbin’s movement, leading to inconsistent tension.

Detailed Steps:

- Turn off and unplug your machine for safety.

- Remove the bobbin and bobbin case from the machine.

- Use a soft brush or lint remover to gently clean the bobbin area. Avoid using canned air as this may push the lint further into the machine.

- Replace any damaged bobbins or cases. Even slight damages can affect the tension.

2. Test the Current Tension:

Why It’s Important: Before making adjustments, it’s essential to know your starting point. This step will show if and how much you need to adjust.

Detailed Steps:

- Insert the bobbin into the machine and thread it as per the manufacturer’s instructions.

- Choose a medium-length straight stitch setting on your machine.

- Sew a test line on a scrap fabric piece, preferably the same type you’ll be working with.

- Carefully assess the stitches. The top and bottom should mirror each other. Look for any loops or puckering that indicate tension imbalance.

3. Adjusting the bobbin Tension Screw:

Why It’s Important: The tension screw is the heart of bobbin tension adjustments. Minute turns can make a significant difference.

Detailed Steps:

a. Too Tight:

- Gently turn the screw counterclockwise. Use a screwdriver that fits perfectly to avoid damaging the screw.

- Opt for small turns, about a quarter or less. This ensures you don’t over-adjust.

- After each adjustment, re-thread the bobbin and sew another test line.

b. Too Loose:

- Rotate the screw clockwise, with the same caution.

- As before, make small adjustments and test regularly to gauge the changes.

Related: Can I Use Metal Bobbins in My Janome Sewing Machine

4. Fine-tuning:

Why It’s Important: The artistry in sewing comes from attention to detail. Fine-tuning ensures your stitches are precisely balanced.

Detailed Steps:

- After each test line, evaluate the tension.

- If it’s close but not perfect, opt for even smaller adjustments on the tension screw.

- Remember, sewing is a blend of science and art. It might take a few tries to get it right, but the results are worth the patience.

5. Maintaining Consistency:

Why It’s Important: Once you’ve achieved the ideal tension, it’s advantageous to have a reference for future projects, especially if you switch between fabrics and threads.

Detailed Steps:

- Observe the position of the tension screw once the optimal setting is achieved.

- Using a non-permanent method, like a tiny dot of nail polish or a soft marker, mark the ‘perfect’ position. Ensure your mark doesn’t interfere with the machine’s operations.

- Periodically check this mark, especially if you feel the tension is off in future projects. It acts as a quick reference to return to your preferred setting.

Mastering bobbin tension might seem overwhelming initially, but with patience and practice, you’ll find it becomes an intuitive part of your sewing process. The above steps are crafted to simplify this journey for you, ensuring every project you undertake with your Janome machine showcases your skills to the fullest.

[su_note note_color=”#f8fcb1″]

Case Study: Adjusting Bobbin Tension on the Janome HD3000 Sewing Machine

Background:

The Janome HD3000 is a heavy-duty mechanical sewing machine, celebrated for its robust performance. However, like all sewing machines, it occasionally requires fine-tuning for optimal performance, especially when it comes to bobbin tension.

The Issue:

Samantha, a long-time sewing enthusiast, recently acquired a Janome HD3000 for her denim projects. While the machine handled thick fabrics beautifully, she noticed the stitches were inconsistent. The top thread was frequently visible on the bottom side of her stitches, indicating the bobbin tension might be too loose.

Initial Assessment:

Samantha referred to her user manual to understand the default bobbin tension setting for the HD3000. She discovered that while the factory settings are typically reliable for most fabrics, heavy materials like denim might require adjustments.

Approach:

- Understanding the Bobbin Housing: Samantha located the bobbin case and the small screw on its side, responsible for bobbin tension adjustments.

- Testing the Current Tension: Using a denim scrap, she stitched a straight line. As suspected, the top thread was visible on the fabric’s bottom side.

- Making Adjustments:

- Tightening: Since the tension was too loose, Samantha used a small screwdriver to turn the tension screw on the bobbin case clockwise slightly.

- Testing: After each minor adjustment, she reinserted the bobbin, rethreaded the machine, and stitched another test line on the denim scrap.

- Iterative Process: Samantha repeated the above steps, making tiny adjustments each time, until the stitches appeared consistent and balanced on both fabric sides.

Results:

After a few iterations, the stitches looked impeccable. The top thread no longer showed on the bottom, and the stitch quality was consistent across the denim fabric.

Follow-Up and Maintenance:

Aware that different projects might need varied tensions, Samantha made it a habit to:

- Regularly clean the bobbin area to avoid lint build-up, which can impact tension.

- Test stitch on fabric scraps before starting any new project to ensure the tension was appropriate.

- Periodically check the bobbin tension, especially when switching between different fabric types and thread weights.

While the Janome HD3000 is designed for heavy-duty sewing and is generally consistent in performance, bobbin tension adjustments are sometimes necessary for optimal results, especially when dealing with varied fabrics. By understanding her machine, referring to the manual, and practicing patience, Samantha was able to fine-tune her machine’s bobbin tension to achieve professional-grade stitches on her denim projects.[/su_note]

- Cleanliness First: Before any adjustment, ensure your machine is free from lint or stray threads. Regular cleaning prolongs your machine’s life and ensures consistent tension.

- Consistency is Key: When testing, use the same thread type and weight. Different threads have varied tensions, which can skew your results.

- Small Moves: The bobbin tension screw is sensitive. Minute turns can have significant impacts. Always opt for smaller adjustments.

- Understand Both Tensions: While this guide focuses on bobbin tension, remember that top thread tension plays a role. Sometimes, issues may originate there, so understanding both is essential.

Guidelines for Specific Sewing Scenarios

Different projects require varied tensions. Here’s a quick guide:

- Thick Fabrics: Materials like denim or canvas might require a slightly looser bobbin tension. Test and adjust accordingly.

- Specialty Threads: Threads like metallic or embroidery can have unique tensions. Always test these separately and adjust based on the specific project.

- Quilting vs. Regular Sewing: Quilting often necessitates a different tension compared to standard sewing, given its multiple fabric layers.

Troubleshooting Common Bobbin Tension Issues on Janome Machines

- Looping/Snarling: Often a sign of loose bobbin tension. Tighten the screw incrementally and test.

- Thread Breakage: This can be due to overly tight tension. Loosen the tension screw slightly and ensure you’re using a quality thread.

- Puckering Fabric: A combination of both top and bobbin tension issues. Adjust both cautiously.

Read More about Troubleshooting Tips – Janome Machines

Caring for Your Janome Sewing Machine to Ensure Consistent Tension

Your Janome is an investment in your craft. Regular maintenance ensures consistent tension and optimal performance:

- Regular Cleaning: Dust and lint can interfere with tension. Clean after each project.

- Quality Threads and Bobbins: Invest in good quality threads. They have consistent diameters, which aids in maintaining steady tension.

- Professional Servicing: Occasionally, take your machine for a professional tune-up. They can catch issues before they become significant problems.

Conclusion

Adjusting the bobbin tension is an integral facet of the sewing process, ensuring each project achieves its highest potential. Particularly with a Janome machine, mastering this adjustment can lead to a significant leap in the quality of your work.

By understanding “how to adjust bobbin tension on Janome sewing machines,” you’re not just tweaking a mechanism but enhancing the overall craftsmanship of your creations. This guide aimed to simplify this process, offering a thorough walk-through and best practices.

In summary, remember that the journey of sewing is filled with nuances. Embracing and mastering each step, especially something as pivotal as bobbin tension, will elevate your projects from ordinary to extraordinary. Happy sewing with your Janome machine!